In a contemporary landscape where efficiency and work quality are paramount, businesses across the globe are continuously in search of strategies to streamline their operations and minimize downtime. Industries are ceaselessly exploring methods to boost efficiency, reduce expenses, and optimize the longevity of their assets, all in the pursuit of conducting business with greater effectiveness and efficiency. At the heart of this endeavor lies maintenance management, a pivotal component that ensures that machinery, facilities, and valuable assets remain in peak condition to attain the coveted pinnacle of Overall Equipment Effectiveness (OEE). Enter Improsys Technologies, a trailblazing force in software solutions. They are poised to revolutionize the landscape with their groundbreaking Maintenance Management Software. This innovative tool promises to completely reshape how organizations approach asset management and maintenance procedures, setting new standards in efficiency and productivity.

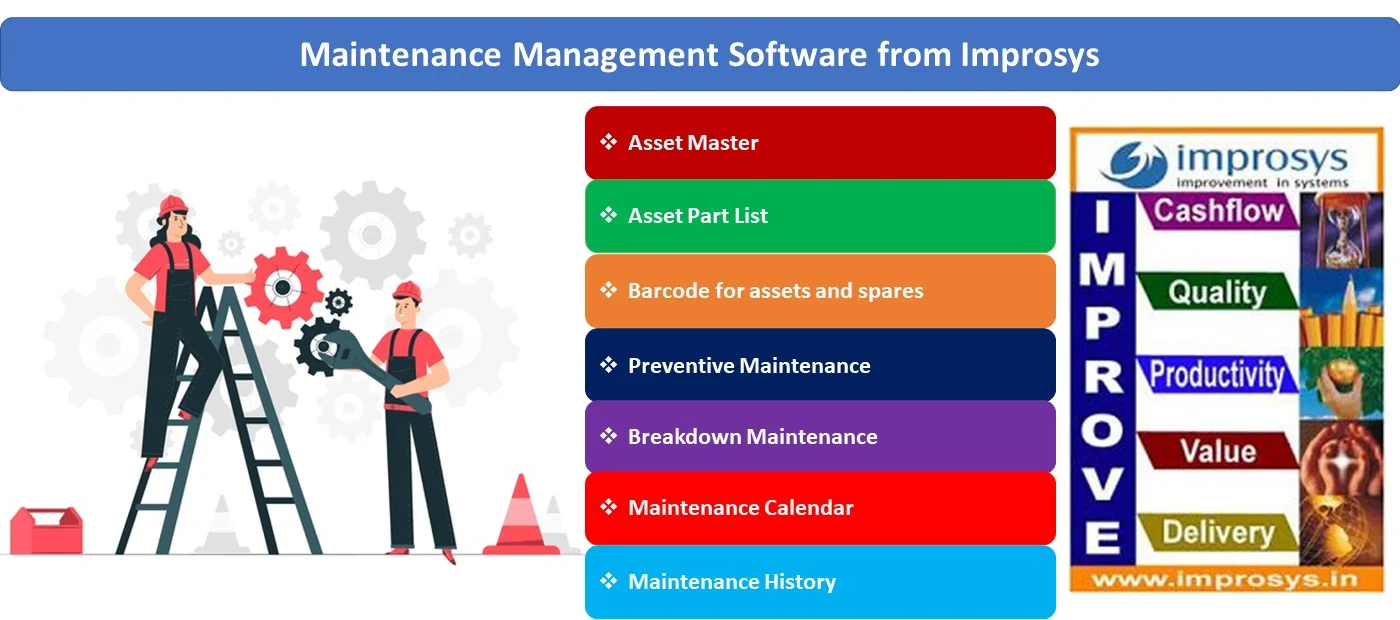

Ensuring the availability of the right components with Asset Spare Part Management. Facility to print Barcodes and QR codes, streamlining asset and spare part identification.

Mobile accessibility allows field technicians to effortlessly update breakdowns, report progress, manage asset information on-site, team can stay informed through the live asset dashboard for real-time maintenance status updates.

Define Preventive and Breakdown maintenance checklist along with schedule of tasks and responsible person. Planned vs completed activities can be monitored.

Work Permit Management feature to define safety checklist before starting maintenance. User has to adhere that the checklist is approved before staring any maintenance activities.

Leep track of warranties and Annual Maintenance Contracts (AMCs) for spare parts. Generate alerts of warranty expirations and AMC renewal dates, and track the same using the AMC dashboard.

Maintenance teams can dispatch assets for repairs, monitor the repair progress, and receive them back after servicing. The reconciliation dashboard ensures that repaired assets are properly accounted for.

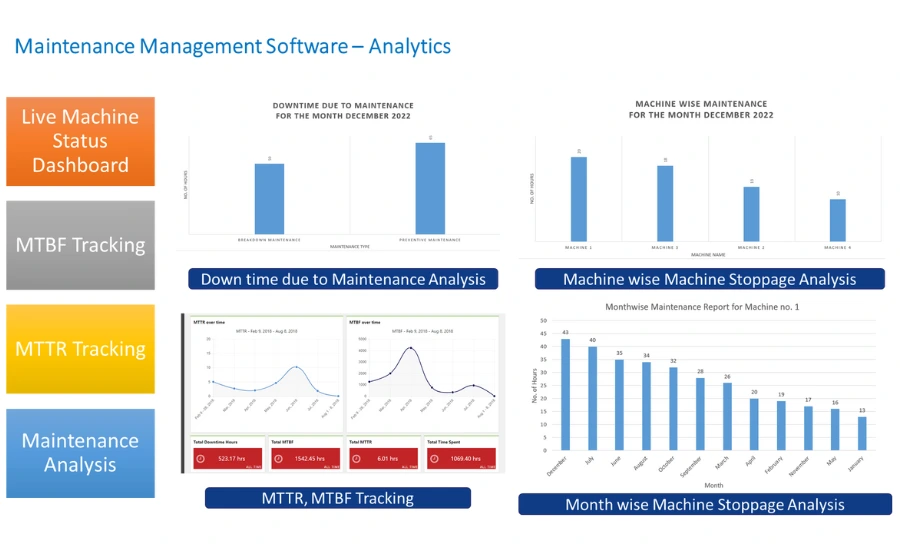

Monitor the status and performance of assets and machines with Live Machine Dashboard. The dashbaord gives a clear view of the current ongoing maintenance activity.

Keep track of effectiveness with KPI Dashboard, focusing on crucial metrics such as Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF).

Receive important updates, alerts, and reminders via email, SMS, or WhatsApp, ensuring that no critical maintenance tasks go unnoticed.

A CMMS keeps you up-to-date organization’s maintenance activities. The software lets you store and attach procedures, error logs, manuals, licenses, photos, diagrams, and schematics to the asset record.

Computerized maintenance management software aids organizations in regularly checking and maintaining equipment and meeting safety standards to prevent malfunction and critical failures.

watchBetter scheduling means that your team is not sitting idle or working overtime, which means work can be distributed evenly and activities can be planned well in advance to avoid clogging of work.

Managing your inventory with a CMMS helps to track parts, and optimize inventory levels. If stock falls below a set minimum, the system will notify the required users to start the procurement process. Users can monitor the stock to avoid out of stock situations.

Maintenance Management Software helps schedule preventive maintenance tasks well in advance for every asset which can reduce the downtimes of equipments and increasing the productivity of the operations.

Maintenance management software tracks parts,history and other miscellaneous expenses when a maintenance work order is completed. This information ca be viewed any point of time by simply scanning the asset barcode.

The Live Machine Dashboard offers immediate, detailed insights into the status and performance of your assets and machines, providing you with a real-time view of their conditions and positions. This feature is accessible from various devices such as desktops, laptops, mobile phones, and tablets, granting you a comprehensive overview of ongoing maintenance activities, ensuring you have all the necessary information at your fingertips to make informed decisions about your assets and equipment.

Maintenance Scheduler is responsible to take a maintenance plan and bring together all the resources needed to complete it. The Scheduling role involves assembling and coordinating the information, people, materials, equipment, along with all the other necessary resources to get the job done.

Planned or scheduled maintenance is a list of predetermined maintenance actions carried out at regular time intervals that are aimed at the prevention of breakdowns. The primary goal of scheduled maintenance is to prevent equipment failure before it actually occurs.

Fast Maintenance Management Software goes beyond basic asset management. It also keeps track of warranties and Annual Maintenance Contracts (AMCs) for spare parts.

By alerting users to warranty expirations and AMC renewal dates, the software ensures that assets remain under warranty protection and are always serviced in a timely manner, helping organizations optimize costs and maintain operational efficiency.

Prioritizing safety is paramount when it comes to maintenance operations. Fast Maintenance Management Software includes a robust Work Permit Management feature that not only streamlines the work authorization process but also significantly enhances safety protocols. It ensures that all maintenance tasks are conducted in a controlled and safe manner, reducing the risk of accidents or incidents associated with unauthorized or unsafe work practices. This feature provides peace of mind to maintenance teams and organizations by reinforcing a safety-first approach to maintenance operations.

Enhance asset and spare part tracking accuracy with QR and barcode integration. Easily generate and assign QR codes or barcodes to assets and spare parts, streamlining the identification process.

This technology enables quick access to asset information and simplifies inventory management, reducing the risk of errors and enhancing overall efficiency.

Measure maintenance team's effectiveness with KPI Dashboard, focusing on crucial metrics such as Mean Time to Repair (MTTR) and Mean Time Between Failures (MTBF).

These metrics provide valuable insights into maintenance processes and help to make data-driven decisions for improvement.

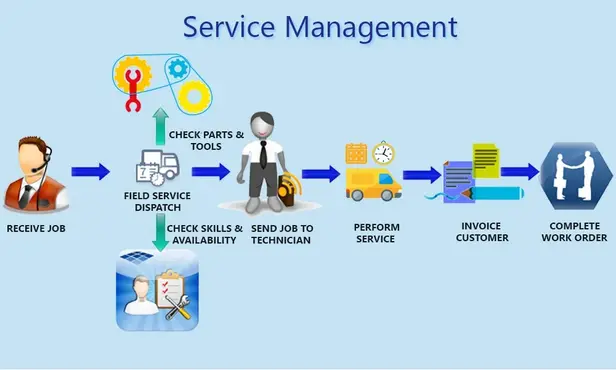

The goal of service management is to maximize service supply chains as they are typically more complex that the supply chain of finished goods. Service Management is thus a managerial discipline focused on a customer and a service. Services must be managed throughout their lifecycle. Softwares provides the facility to record the incoming calls & update the incoming service request.

Also software has provide first inspection report of defective components & defective products.Software also identified AMC product,Free servicing etc.

In industry, total productive maintenance (TPM) is a system of maintaining and improving the integrity of production and quality systems through the machines, equipment, processes, and employees that add business value to an organization. Software has identifies various reasons of stoppages of machines.Ths software has preventive maintenance facility which helps to reduces the stoppages of machines. The software is facility to find out the OEE (Overall Equipment Effectiveness) which is indicating productive maintenance effectiveness.

Evolution of TPM

Break Down Maintenance : Restore equipment condition after break down Preventive Maintenance : Regular inspection to see if anything is wrong. & Repair before break-down.

Productive Maintenance:Preventive Maintenance + Consideration of over-all efficiency and effectiveness of equipment.

Planned maintenance system helps organizations track,analyze,manage and report on energy consumption, as well as automate the validation of utility bills and the allocation of costs internally. Our value added software solution defines a transformation strategy, prioritizes your needs with right technologies which optimized your cost and time.